- LED curing technology provides significant energy savings and aligns with California’s stringent environmental regulations

- Equipped with the latest exceptional color control and management tools unique from Koenig & Bauer

- Custom folding carton package delivers premium packaging solutions using sustainable materials

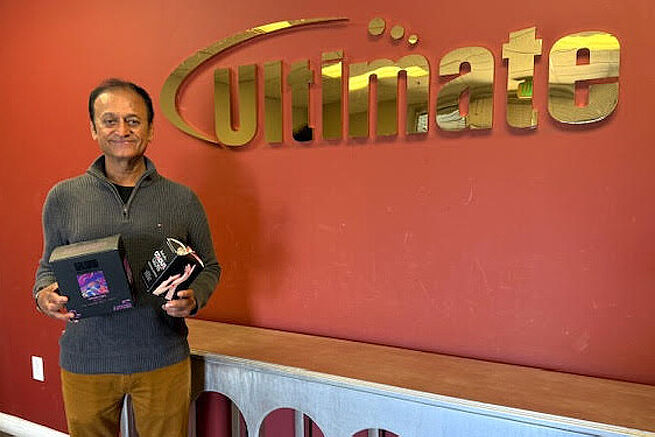

With a growing trend towards both high-end, sustainable packaging and shorter-run custom projects, Ultimate Paper Box (UPBX) took the decisive initiative to add a new sophisticated mid-size Rapida 106 41-inch eight-color LED sheetfed press to its City of Industry, CA pressroom from long-time press manufacturing partner Koenig & Bauer. “As our elite brands seek more eco-conscious solutions and faster turnaround times, we want to continue to be well-positioned to meet those demands with our new technology and dedicated team,” says Janak Patel, UPBX’s president.

Ever since Patel established his southern California printing business, major brands have been attracted to his emphasis and commitment to innovation, quality, and sustainability. The new Koenig & Bauer press investment underscores Patel’s dedication to provide his customers with the best possible packaging solutions while adopting environmentally responsible practices.

“Our philosophy has always been to invest in cutting-edge technology to stay ahead of the curve and deliver eye-catching packaging solutions,” says Patel. “This new Koenig & Bauer press enhances our production speed, precision, and color consistency, giving us the ability to take on more complex and high-end packaging projects while improving overall efficiency.”

Patel specified that the new Rapida press be equipped with a variety of standout features such as advanced color control, fast makeready times, and LED drying technology. The ability to print with greater accuracy, reduce waste, and streamline workflow were major factors in his decision. These features allow UPBX to deliver consistent, high-quality results with increased efficiency to a diverse range of industries, including food and beverage, cosmetics, pharmaceuticals, and consumer goods.

As market demands evolve, UPBX continues to expand its reach, particularly in premium packaging solutions and sustainable materials. Color accuracy and consistency are critical for brand integrity, especially in luxury and consumer packaging. With Koenig & Bauer’s state-of-the-art color management system, says Patel, UPBX can ensure that every run maintains the highest level of production, reducing color variation and eliminating costly reprints.

Operating in California requires UPBX to be exceptionally aware of the state’s stringent environmental regulations. The Rapida’s LED curing technology allows the firm to reduce emissions, lower energy consumption, and eliminate harmful solvents. “This investment reflects our ongoing commitment to sustainability and regulatory compliance,” says Patel. Equally impressive is the significant energy savings and improved drying speed and efficiency derived from the Rapida’s LED curing technology.

This key investment marks the fourth sheetfed press from Koenig & Bauer. It will join the firm’s current large-format press models on the production floor, allowing UPBX to expand its capabilities and increase capacity. The decision to invest in a medium format press was driven by customer demand for shorter-run, high-quality packaging solutions. While large format remains crucial for volume-based production, this new press allows UPBX to be more agile and responsive to market needs, especially for premium and customized packaging solutions. As UPBX continues to experience tremendous growth, investing in the latest technology ensures that the packaging supplier can meet rising demand without compromising on quality or efficiency.

UPBX has also invested in Koenig & Bauer post-press equipment, which, says Patel, has optimized its workflow, finishing capabilities, and turnaround times. “With increased automation and accuracy in our post-press department, we can streamline production, reduce waste, and enhance the final quality of our folding cartons, making us more competitive in the market,” he adds.

“We’ve built a strong, long-term partnership with Koenig & Bauer,” says Patel. “Since our very first press installation in 2008, they have provided us with the most amazing technology and highest productivity. Our record-setting growth and success can be attributed in part to Koenig & Bauer’s cutting-edge technology, reliability, and exceptional support. We trust their solutions to elevate our production capabilities and keep us at the forefront of the industry.”