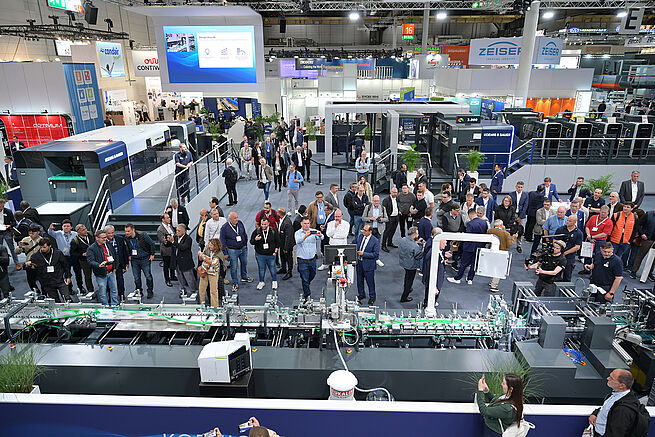

- Leading commercial and packaging firms are drawn to Koenig & Bauer’s innovative finishing technology

- Boosting efficiency, reliability, and cost-effective solutions

- Entry level machines are built as robust as the larger more industrial machines

As printers recognize the importance of a technologically advanced finishing department, Koenig & Bauer celebrates its market success with its renowned array of high-performance post press solutions throughout the US and Canada. Its popular line of folding gluers and die cutters are the preferred choice among printers due to the unique features and benefits of its technology along with the service and support that accompanies Koenig & Bauer’s traditional method of doing business with all of its products.

“With the higher speeds of printing presses, there’s a recognition among printers and packaging firms to be equipped with the most automated finishing equipment to alleviate bottlenecks in the finishing department,” says Tom Fitzgerald, director of post press and corrugated products at Koenig & Bauer (US/CA). “We’re proud to offer all European made machines that are 100 percent manufactured and wholly owned by Koenig & Bauer. Our customers cite the high quality of build of our post press equipment in which entry level machines are as robust as our larger industrial machine with identical longevity. What’s more, our finishing equipment is integrated with our German team in Radebeul, in which the same synergies between press and post press technology are shared. Our post press customers are provided with a dedicated service manager that is cross trained for the utmost satisfaction.”

Koenig & Bauer has recently added several new finishing systems and features focused on automation, efficiency, and expanded capabilities for packaging and label production. Key finishing innovations include the CutPRO X 106 rotary die-cutter and the Omega Allpro folder gluer series along with flatbed die cutting solutions such as the popular Ipress series and innovative CutPRO Q 106 SB.

CutPRO X 106 rotary die-cutter is a new rotary die-cutter designed for label and packaging production and features high performance with rapid job changeovers. It can achieve speeds of up to 16,000 sheets per hour, keeping pace with high-speed offset presses. A “Click & Cut” system allows for job changeovers in under five minutes. Plus it can handle substrates from ultra-thin in-mould films to label papers and board.

As one of the most powerful flatbed die-cutters in its class, the CutPRO Q 106 SB provides maximum performance in industrial folding carton production with speeds up to 9,000 sheets per hour. It offers die-cutting, stripping and blanking in a single machine pass and handles a broad spectrum of substrates, from 90 g/m² paper to solid board up to a thickness of 1.5 mm or corrugated board up to 3 mm.

The Ipress is available in a 106 PRO S and PRO SB medium format flatbed die cutter that is ideal for folding carton and packaging applications, as well as industrial commercial or packaging printing applications. It can expertly process sheet sizes up to 750 x 1,060 mm, delivering precise and high-quality print products. For those seeking a large format solution, the Ipress 145 PRO and 145 K PRO offer extraordinary speeds of up to 7,000 sph and sheet formats of up to 1,050 x 1,450 mm. The new Ipress series is now available with the highly sought after Cut2Print system for exacting register.

The Omega Allpro folder gluer series is a versatile and automated system designed for high-speed folding and gluing of complex folding carton styles. Its automated processes and job memory functions significantly shorten setup times. Users are offered a variety of folding options including straight line, crash lock, and four- and six-corner boxes. The Allpro 110 model can achieve a belt speed of 400 m/min, maximizing productivity. The new Omega Alius 90 folder gluer offers high speeds and intelligent automatic setup. This new folder gluer features full servo control, intelligent automatic setup with calculation from carton drawing, and high-speed throughput of up to 600 m/min.

Leading commercial and packaging firms are drawn to Koenig & Bauer’s innovative finishing technology. They praise the firm for its custom solutions and experts who provide in-depth knowledge and find solutions for their needs.

- Ultimate Paper Box, a southern California printer, attributes its Koenig & Bauer post-press equipment for optimizing its workflow, finishing options, and turnaround times.

- At Ingersoll Paper Box its Koenig & Bauer Optima 106 K die cutter is giving the firm added capabilities, faster production speeds, and broadened its customer base.

- Battlefield Press cites its Koenig & Bauer Allpro 110 folder gluer for its continued growth, greater efficiency, and the ability to save its progress for repeat orders or similar sized orders thus improving its overall production and set-up times.